Ten years — Ronco Construction and the University of Nebraska-Lincoln’s Continued Partnership

In the heart of the University of Nebraska-Lincoln’s (UNL) East Campus stands a tribute to both history and modernization: the East Campus Utility Plant (ECUP). Originally built in 1915 as a coal-fired heating plant, the facility has evolved with time but remains constant to one goal — ensuring year-round heating and cooling for UNL’s East Campus.

As one of the oldest buildings on the UNL campus, the ECUP symbolizes a rich heritage of service and strength. Despite its age, the plant operates without a hitch, thanks to thorough maintenance and constant management. However, as technology and environmental standards have evolved over the years, major expansion projects have become necessary. And for the last 10 years, UNL has leveraged the same trusted partner to complete the work: Ronco Construction.

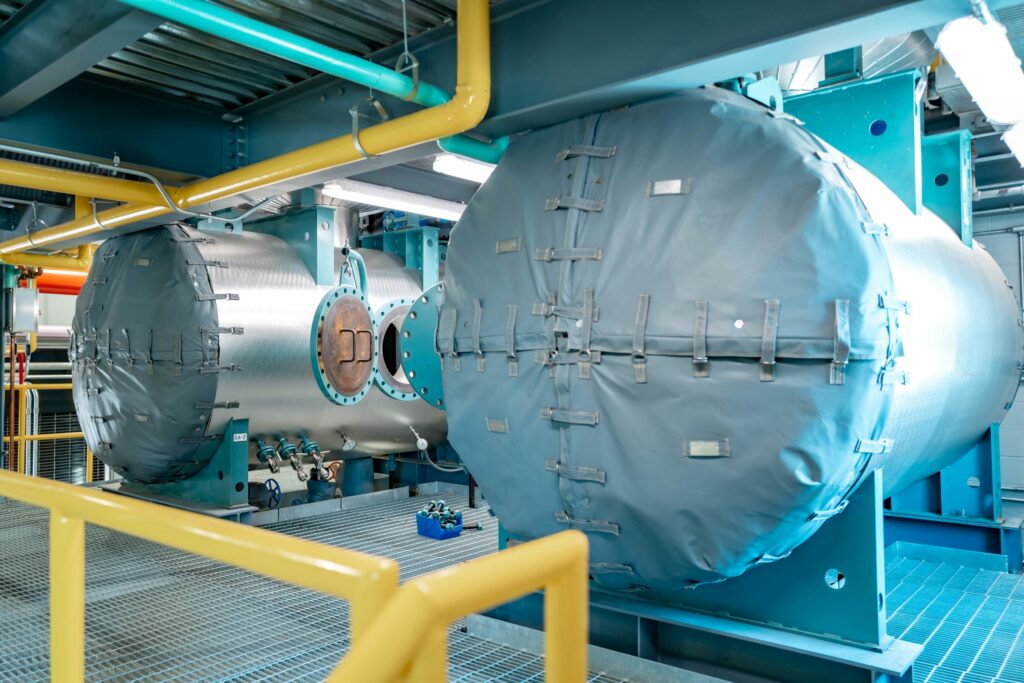

The latest undertaking at the ECUP is a 4,200 SF CMU construction building, designed to house two mega boilers and features steel catwalks, 10-foot-thick concrete slabs, and garage doors. This project marks Ronco’s third project at UNL and the fifth collaboration with the University of Nebraska.

An Above-the-Box Approach

Back in 2012, UNL needed to remove and replace two chillers and build an addition to the City Campus Utility Plant (CCUP). What makes the CCUP special is that it supplies heating and cooling to the entire UNL City Campus as well as other government buildings in Lincoln’s downtown loop, including the state capital. The other contractors bidding for the job planned to move the chillers out through the building’s front windows. However, running directly underneath the ground in front of the windows were two 36-inch steam lines and two 36-inch cooling lines. Now, these chillers are large — weighing about 100,000 pounds each — and the weight of them would crush the pipes below. So, the project had to account for an extra two months in the schedule to prepare the ground and additional materials (i.e. more cost) to ensure that didn’t happen.

The Ronco team decided to think outside the box. Or rather above the box. Their proposed plan was to take the roof off the existing building, remove the old chillers and install the new chillers by using a 300-ton crane, and then put the roof back on. And the plan worked perfectly — they did it in one day, and in the snow no less. That feat not only showcased Ronco’s capabilities but solidified Ronco’s reputation as a problem solver and innovator.

Perfect Coordination

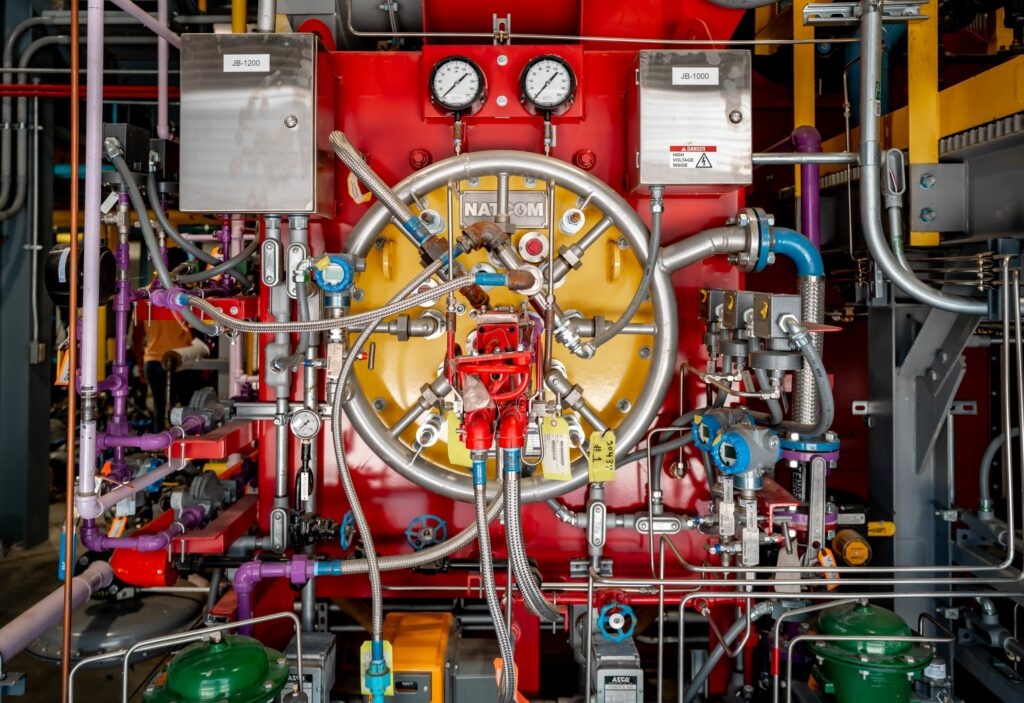

In the latest project at UNL, the challenge wasn’t crushing underground pipes. It was the scope of work and the number of trade partners and stakeholders involved.

“It was essentially like high-stake Legos, piecing together all the equipment that had ‘some assembly required’,” explains Nate Bledsoe, Ronco’s project manager. “I was constantly learning the science behind how the system worked so efficiently — and it was fascinating.”

Beyond coordinating the different phases of work, the other key piece to success was keeping everyone informed. What work was happening when and who was doing the work. Communication had to be seamless. Terry Paulson, Ronco’s on-site superintendent, was the master at this and made sure updates and passing words got to the right people.

“Terry played a large role in ensuring information got to where it needed to go. Lots of phone calls, emails, on-site meetings, photos and idea sketches made this project possible,” explains Kaylee Tobiason, the project engineer.

In the end, teamwork between all of those involved made the project successful. The entire project team noted their favorite part of this project was the team atmosphere that UNL has created.

“Working with UNL for this project was very collaborative and we met regularly with UNL personnel to ensure we were meeting the goals of the project,” Tobiason said. “We were committed to working together to provide the best possible product at the end of the day.”

A Long-Lasting Partnership

With the ECUP project completed, Ronco remains committed to supporting UNL’s mission of excellence in academics and progression. With each project, Ronco strives to surpass expectations, delivering results that stand the test of time and contribute to a brighter future for generations to come at the university.

“I believe the reason UNL enjoys working with us is because we don’t pretend to be someone we’re not. We leaned on UNL’s expertise to complete this job and balance that with our own experience and expertise. That way we can continue to complete these types of jobs more efficiently in the future,” Bledsoe said.